Product Description

This listing includes 1 unit of motorized valve 2 way, DN25(1" BSP)

MODULATING: 0-10V (proportional)

POWR VOLTAGE: 24VAC/DC

Application:

Equal percentage flow characteristic guarantees the valve performances of stability. Control ball valves are widely used in HVAC system, heating system, water treatment equipment, and water running control in industrial automation, such as: AHU, flesh air-handling unit, differential pressure control unit and heat exchanger for flow regulation and on/off control.

Operational mode

this control ball valve is motor-operated by the actuator. The actuator is controlled by proportional control system and move the ball of the valve, to the opening position dictated by the control signal.

Technical data

Valve body:

Medium: cold/hot water, with 50% glycol Temperature of medium: 2°C...90°C

Rated pressure: PN2.0 Pipe connector: internal thread

Ambient temp. range: −5…+60°C; 0…90%RH Size: 1"

Valve type: 2-way Flow characteristic: equal percentage

Material

Valve body: forged brass, Hpb59-1 Seal: ball: EPDM+PTFE

Ball: stainless steel brass stem: EPDM

Valve connector: PC Valve spindle: aluminum alloy

|

DN(mm) |

Inch |

Valve pipe |

Kvs(m3/h) |

Pvmax (MPa) |

Ps (KPa) |

|

DN25 |

1" |

2 way |

10 |

2.5Mpa |

1400 |

Actuator

24VAC/DC±15%, proportional (0-10VDC)

Output torque: 4N.m Angle of rotation: 90°

Manual handle

Automatic overload protection system

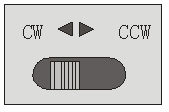

Manual selection of ball rotation direction: C.W. /C.C.W, factory setting is C.W.

Protect rank: IP54

Function (proportional type)

The actuator is controlled by a modulating on/off, 3-piont, and proportional control signal, using high transmitting ratio gear drive to fix and lock.

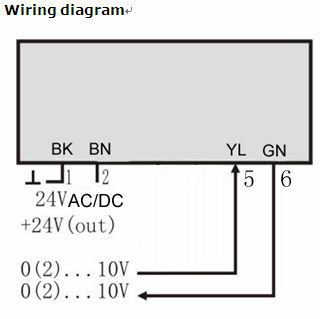

Black wire and brown wire are the power wire.

Yellow wire accept 0-10V control signal to control the valve’s open angle.

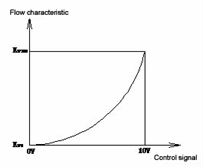

Flow characteristic

Input 0-10VDC control signal

Flow characteristic: equal percentage

Flow range: 0%-100%

|

Working Voltage |

Actuator type |

Output torque |

Consumption |

Valve body |

|

24VAC/DC±15% |

0(2)-10VDC |

4N.m |

3VA |

DN25 |

IIInstallation:

1. Ensure that the valve body is in the full open status.

2. Ensure that the actuator is in the fully open position as the follow picture:

3. Aligning the valve stem, press down the aluminum alloy spindle.

Change of running direction

The rotation can be reversed by pushing the CCW/CW switch on the casing.

Factory settings: "CW"

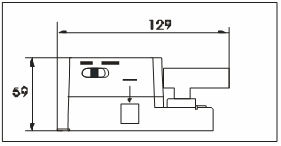

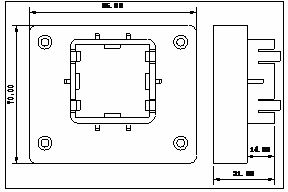

Dimension and Wiring

Connector Dimension

Current Reviews: : total 0 reviews

This product was added to our catalog on Sunday 26 January, 2014.